|

Here is a video giving a little more understanding of how we move houses and keep what history we can in Arizona!

0 Comments

Our crew is currently working at a job in Tucson, Arizona moving buildings to create room for a new road that is being built. We just finished moving the second building and have five more to go. The first two buildings have been rolled to the back of the property and are being held there until a new foundation is poured for them to sit on. Moving this building took our crew about 13 days to complete everything from the preparation to the rolling and moving. Recently the weather has not been quite permitting, but we were able to continue working and get another house moved out of the way. We are now setting up to start working on moving the next house in about one and a half weeks. This is one of our bigger jobs that we will be spending quite a bit of time on and will continue to write updates and posts about our progress. Be sure to check out the rest of our posts and keep informed with our moves!

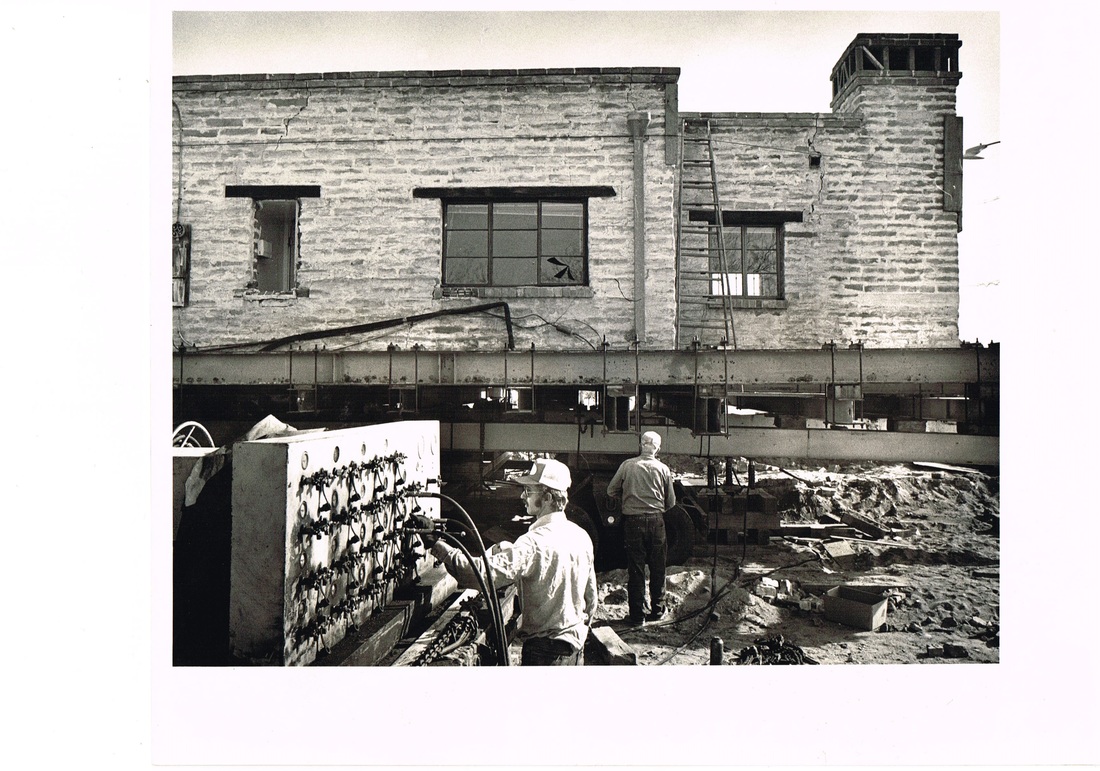

Currently we have a crew down in Tucson, AZ working on a new move. So far we have moved the first out of a total of seven houses. This first one is the oldest of the seven, being built in 1920. The house is made of two rows of red brick and stucco on the outside with a fire place and cooking chimney on the inside. The building weighs 114 tons (228,000 lbs.) and took approximately three weeks to move. The beginning of this process is to prepare the house for the installation of beams. We cut holes through the concrete stem and created trenching underneath to allow room for the beams. Then angle irons are installed around the house to support the bricks. Once the house has been properly prepared for moving we start the rigging process. Each beam must be shimmed and prestressed to support the weight of the house. Prick timbers (large beams) are installed on the outside and bolted to crossbeams to create a frame for to fit the building. The building is then jacked up using a unified hydraulic jacking system so that we can install a rolling track and rollers. Using two 12,000 lb winches the house was rolled 76 ft. The house will be stored at the back of the lot while a new foundation is put in, and then will be moved back to the new foundation.

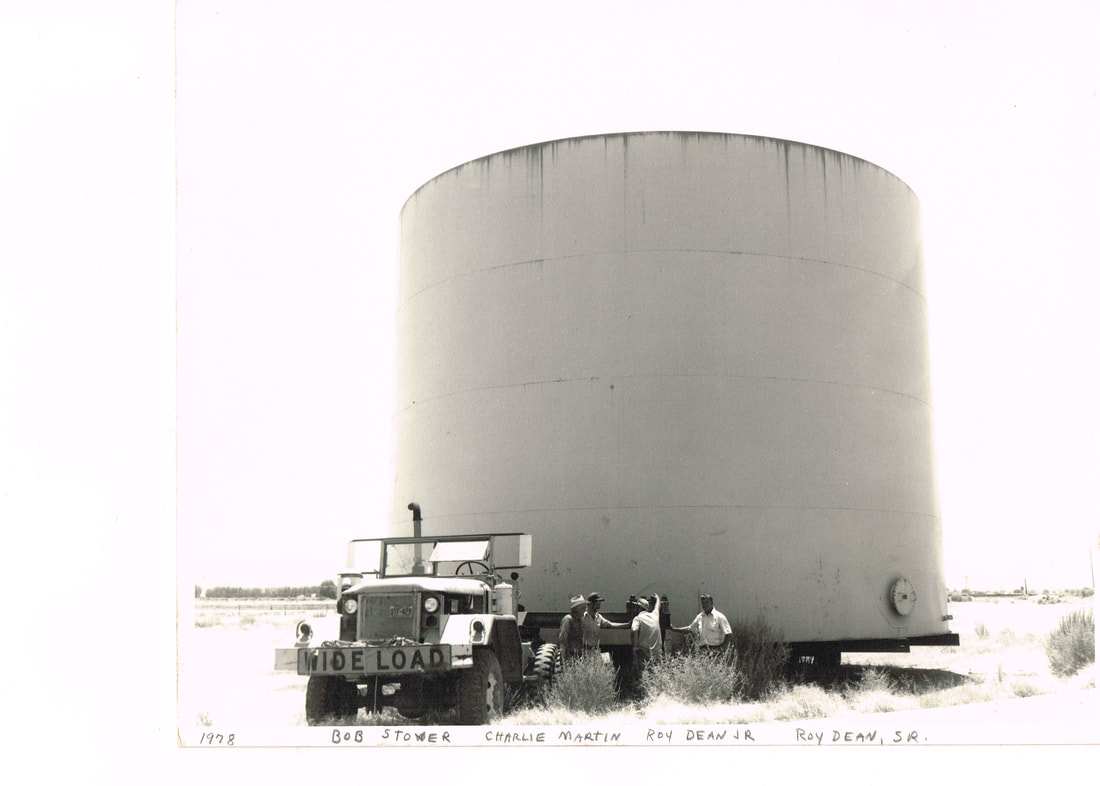

Another move we have made that was not a typical structure was some old fuel tanks. These tanks were used after WWII to hold fuel to be used during the frost that would harm the citrus plants that returned soldiers were farming. The government gave the soldiers jobs of growing citrus trees when they came home, but when the frost came they needed a way to protect the crops, so the fuel tanks held the fuel that was used to keep heat over the crops. Eventually the tanks were being re-purposed and needed to be moved. To move these tanks, we used a specialty truck that we called “Trojan Truck”. These tanks were so large that it took one and a half days to go two miles down the road. One tank was taken a part and put back together in Mexico. Overall these tanks were somewhat difficult to move, but we got it done and can add another successful move to our resume. Moving houses is the main part of our job, but sometimes we are challenged with new types of structures. This time it was an 80 ft tall tower that took us 8 days to move. This tower was too large to move as one piece, so we had to take each layer apart and move it separately. There were eight layers, and we moved a layer a day. We had to slowly jack up the tower and cut it apart piece by piece, and then once we moved it all we put it right back together. This move was exciting because it was something new that we were able to experience as well as accomplish.

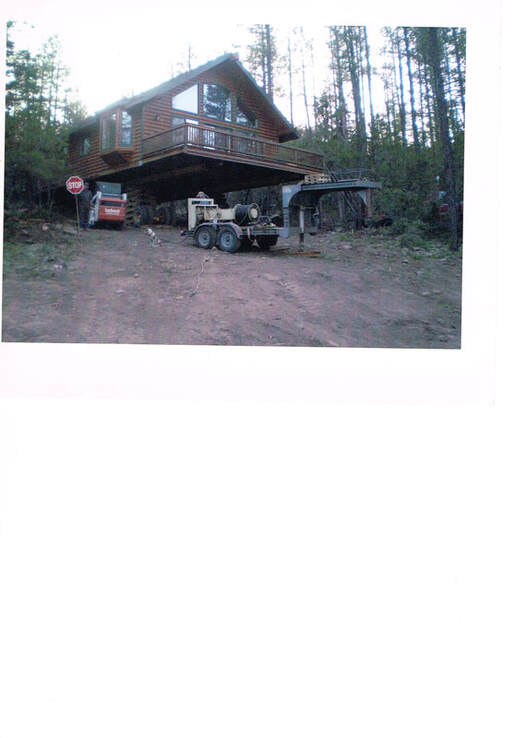

Many people ask if we ever look at a building and think to ourselves, “Man this just can’t be moved,” and our answer is no almost every time. The one exception to this answer is a move we made up in the mountains. This move was near to the impossible side, but that did not stop us, we still dove right in and began to work at it. Seven cabins were to be moved half a mile over. A half a mile doesn’t seem that far, well unless you are moving seven log cabins it does. The distance of the move was not our biggest concern, nor the number of cabins, but rather the location. The cabins were being moved on the side of a mountain, and this mountain was extremely steep. So steep that the front of the 40-foot house was sitting on the ground while the back was sitting 21 feet off the ground. To make this move we had to use every trick we had in our book, as well as come up with some new ones. Using our old and new tricks we were able to get the job done and appreciate a little bit more the ease of some of the other jobs we have done. At the end of the day we were relieved, as well as feeling accomplished of the job we had just completed.

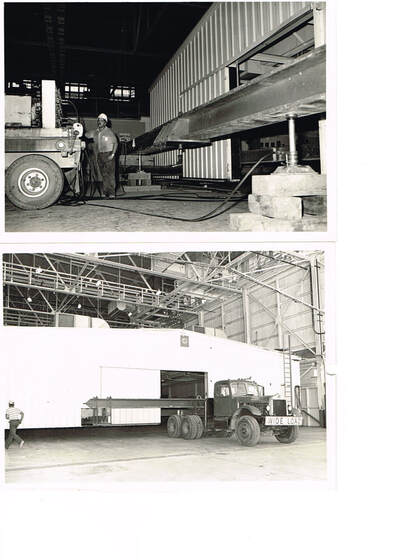

Moving buildings can be difficult sometimes, and this time was one of those times. This building was particularly different from others we had moved before. It was a machine shop that was built inside of a larger shop/hanger in the mid 70’s. Many challenges came from working with not only one building, but two buildings. One of these challenges was that the building would barely fit through the main building. The shop that was being moved was 60ft wide and 120ft long. To be able to relocate the shop the crew had to load it low enough that the roof wouldn’t hit the ceiling of the main building. Another big challenge was working inside two metal buildings in 100-degree weather caused dehydration and sickness. The three-man crew struggled with the heat making it harder to work, however, they got themselves hydrated and finished the job. This also taught them a lesson of the importance of keeping yourself healthy and hydrated always. It took two weeks to fully move the building out and to another location on sight. The shop is still in use today since its relocation.

Our company was founded around the 1950’s by Roy Dean Sr. in the mechanic shop he worked out of. He was known in town as the guy that could fix anything and help anyone. This brought many people his way with all kinds of different things, one day someone came in and asked him if he could move a house for 200 dollars. He said yes and got right to it! This house was a one-bedroom cotton picking house that needed to be moved to another location. He used telephone poles and put them under the house. With the telephone poles to hold up the house he then drug the house to the location it was needed, and the move was successful! People heard about this and more began asking him to move other buildings and houses. He started to build his own house moving equipment to use and by 1953 he was a full-time house mover. He bought out a company so he could be licensed and continued his trade. Roy Dean Jr. grew up in his father’s footsteps and learned the trade during summers when he was not in school. At just 12 years old he was driving a tool truck behind the main truck when they moved a house 100 miles. He felt so good to be a part of the crew at such a young age and continued to be apart of it. When he was 18, he was the foreman of his own crew. He continued to work in the family business as he grew up and eventually took over. He still runs the business today and enjoys doing it. “You get a sense of accomplishment after finishing a move that you can’t get at a regular job.” Says Roy Jr. Our company has been in continuous business for 66 yrs., going into the third generation of Structural Movers.

One of our previous moves had a lot of history involved in it, and that is what made it special. In Cottonwood, Arizona an old Catholic church needed to be moved to create space for a new Hospice building. This church had ties to many of the families that lived there, and they did not want to see it be torn down. This was a piece of their history. The church was relocated on the same property of its original location, to follow the Catholic Church’s stipulation that the building be preserved after they sold the property. A new Hospice center was built by the Verde Valley Medical Center in the original location of the church.

The church was a wood framed, stucco structure with seven solid concrete columns on each side. The building weighed 320,000 lbs. (160 tons) and rolled on moving skates 140’ sideways and then 120’ end way. All though this move was challenging and large, everything was moved intact and the church still stands. The house moving business is one that may be underappreciated as to environmental, historical, economical, and sometimes just sentimental savings. House and structure moving helps communities grow while enabling preservation of their history. The industry has been serving communities for many years, dating back to the 1700’s in the USA. Today, many buildings have been or are being destroyed and hauled to a landfill making way for newer buildings or to create larger roads. Each building that is destroyed is apart of our past. We pride ourselves in being able to conserve these buildings, and the way to do it is with house moving! By preserving these buildings more people will be able to re-purpose and enjoy them for the future.

Along with the preservation of historical buildings, structure moving also can save taxpayers money. This is because government buildings can be relocated to wherever they are needed rather than having to spend money and rebuild with every move. The border patrol has been undergoing changes and relocating their stations. In being able to relocate some of the structures, our tax money to rebuild total new stations is saved. This concept also applies to any other government structure that has been relocated. Saving money is always great, but so is saving our resources! Structure moving is one of the largest recyclers in the country. With structure moving the need for new materials is at less of a demand. It is easier for people to reuse their old buildings this way, and not have to build new. With reusing materials, we can save some of the resources for other needs in our communities. Saving history, money, and resources, this is what house and structure moving does for your community! If you meet a structure coming down the road, be glad not mad, the time your held up may be your contribution to a great thing. |

Archives

May 2020

ContributorsRoy Dean |